Audio aficionados often revere filters that incorporate inductors, and for good reason. Designers like Rupert Neve, Bob Moog, and the engineers at Abbey Road Studios understood the unique sonic potential of inductors and used them extensively in their iconic EQs. These filters, like the legendary Pultec EQP-1A, are sought after to this day for their warm, musical character.

What sets inductor-based filters apart is their unique properties. For one, the phenomenon of core saturation can introduce subtle harmonic enhancements, adding richness to the sound in a way that RC filters simply don’t. Additionally, the inductive reactance of these components interacts with capacitors to create resonant circuits, giving these filters their distinctively smooth and dynamic tonal shaping capabilities.

Products like the EVE Equalizer, we craft precision multi-tap inductors in-house, not just to meet the demands of our designs but to define our own sonic fingerprint. The result is a unique blend of craftsmanship and sound that’s undeniably our own—and, let’s be honest, totally badass.

What is an inductor? How does it work?

This can be complicated, but I’ll try to make this is easy as possible to understand. Conductive materials, like copper wire, naturally have three basic properties: resistance, capacitance, and inductance. Resistance is the most noticeable—it’s what makes wires heat up when current flows. The other two, capacitance and inductance, are much smaller and usually don’t matter unless the wire is shaped in a specific way, like a coil or in close parallel with another wire.

Now, let’s talk about audio signals. These are alternating currents (AC), meaning they flow back and forth in the wire. Think of them as wiggling back and forth—slow wiggles are low-pitched sounds, and fast wiggles are high-pitched. As this signal moves through a conductor, the wire’s properties can affect how the signal wiggles.

Inductance is particularly interesting. It’s the property of a wire that resists changes in the current flowing through it. When electricity flows through a wire, it creates a magnetic field around the wire. If the current changes—like it does in AC signals—that magnetic field changes too, and this changing field pushes back against the current. This “pushback” is stronger at higher frequencies, which means inductance naturally blocks or weakens high-pitched sounds more than low ones. This effect is called inductive reactance.

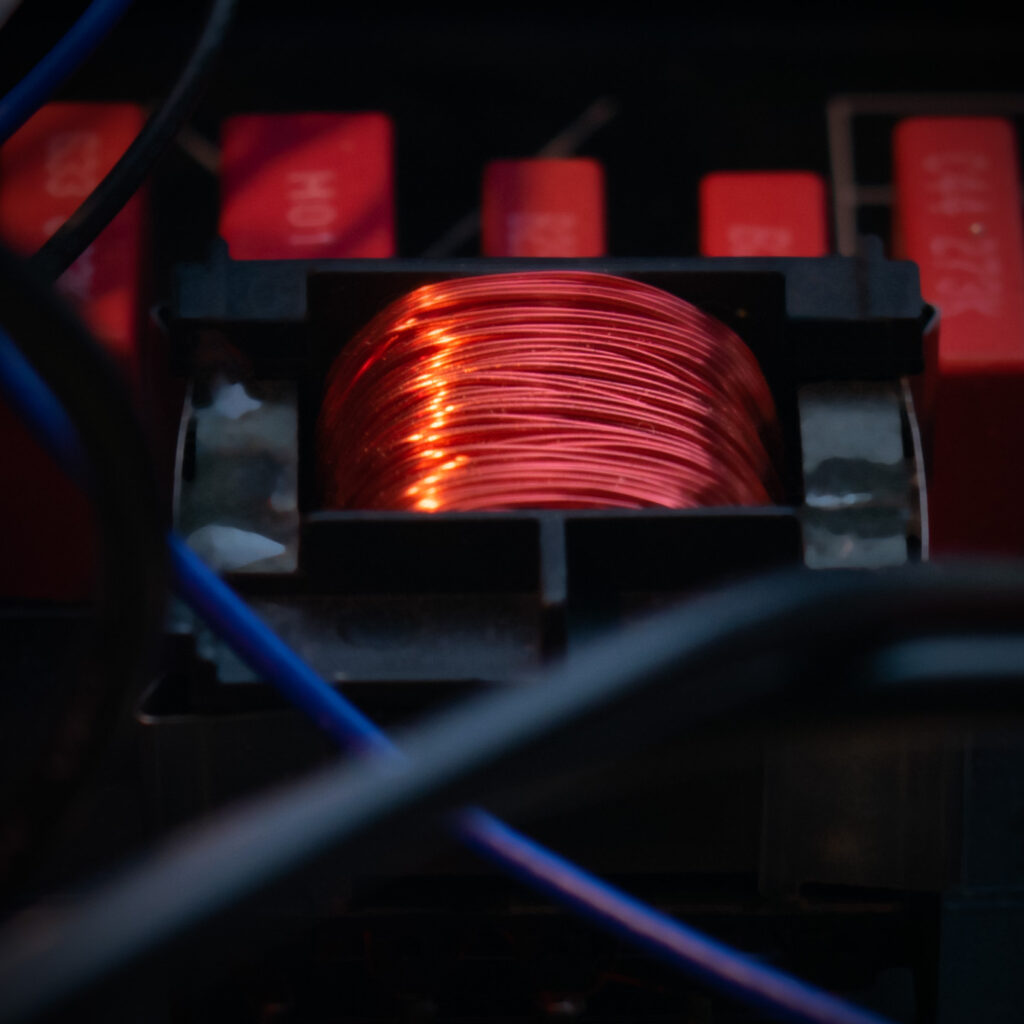

Inductors are specially designed components that take advantage of this property. They’re usually just coils of wire wrapped around a core, which could be air or a magnetic material like iron. The more loops in the coil, the stronger the inductance. We can tweak the design by changing things like the size of the coil or the type of core material to make inductors that block specific frequencies. This makes them super useful in things like audio filters, where you want to shape the sound.

Magnetic materials, like iron, are great at directing the magnetic field created by the wire. This makes them perfect for the cores of inductors and transformers. The ability of a material to “carry” this magnetic field is called magnetic permeability, and different materials have different levels of it. Engineers choose core materials carefully because they affect how the inductor works. For example, some materials can handle really strong magnetic fields, while others might behave differently at high frequencies. By combining these elements, inductors become powerful tools for controlling electrical signals—including the sound we hear.

If you’ve followed along so far, great! If not, that’s ok. its complicated. In essence we can use an inductors ability to “resist” current at different frequencies in the audio spectrum. Using additional components along with inductors, we can create a beautiful tone circuit.

Elektrophonik Inductors

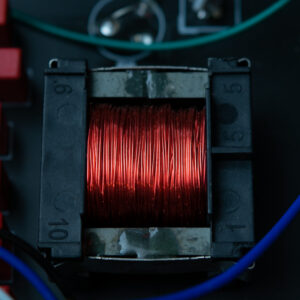

In the EVE Equalizer, we need multiple inductance values. Instead of using multiple inductors, we use one large inductor called a multi-tap inductor. We just “tap” off from different parts of the coil to get different inductance values. Its much more efficient and space saving to do it this way, but just as effective.

At the heart of the inductor is the core. We start with two ferrite cores. It’s what is carrying our magnetic flux. It is just ceramic that is impregnated with iron powder. Using a calibrated coil of wire, we can measure these cores to find their exact magnetic permeability. Since every core is different, and can be different up to 20%, we need to precisely measure them first before we start our design. Each inductor is built for it’s selected core.

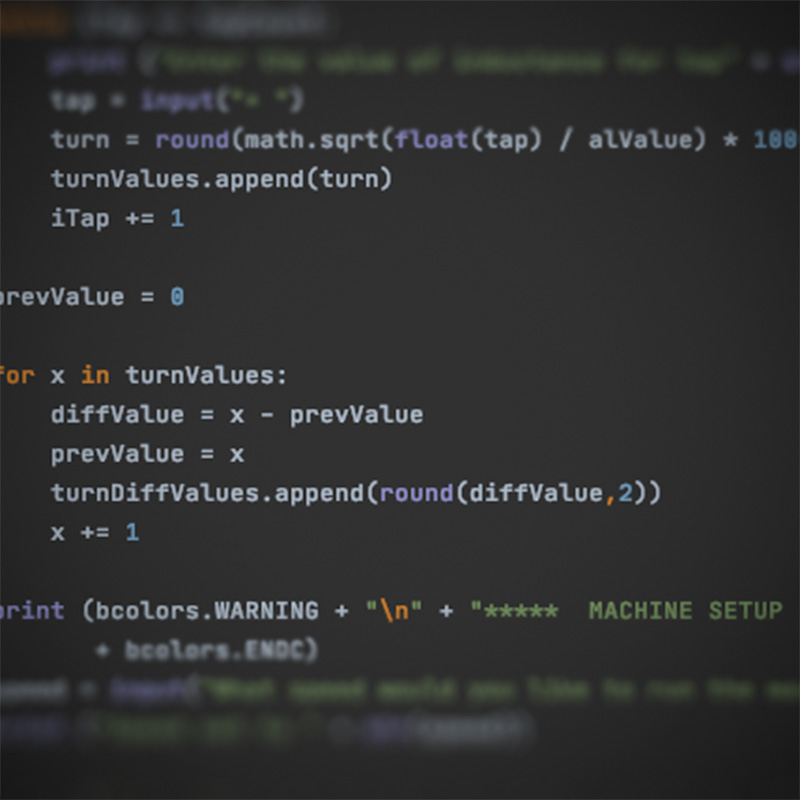

Now that we’ve figured out the cores permeability, we can figure out the specifics to make our coil of wire around it. Every inductor is born from it’s core, and every one is unique. This is where math starts getting very complicated. Because we need to make a ton of these things, we’ve created our own software to make the math process go faster. It’s no fun doing calculations all day.

Using our software, we can enter all of the values we need to make any inductor, based around the selected core’s permeability. Then it figures out exactly what we need to make a custom inductor based on the core. Next we need to know the wire diameter, length, number of coils, bobbin width etc… luckily we’ve also told our software how to factor all of that in as well.

Then our software performs double duty. It takes all of our initial requirements, compares it with the permeability of the selected cores, then calculates everything we need to make the perfect sounding inductor. It takes this information and turns it into machine code.

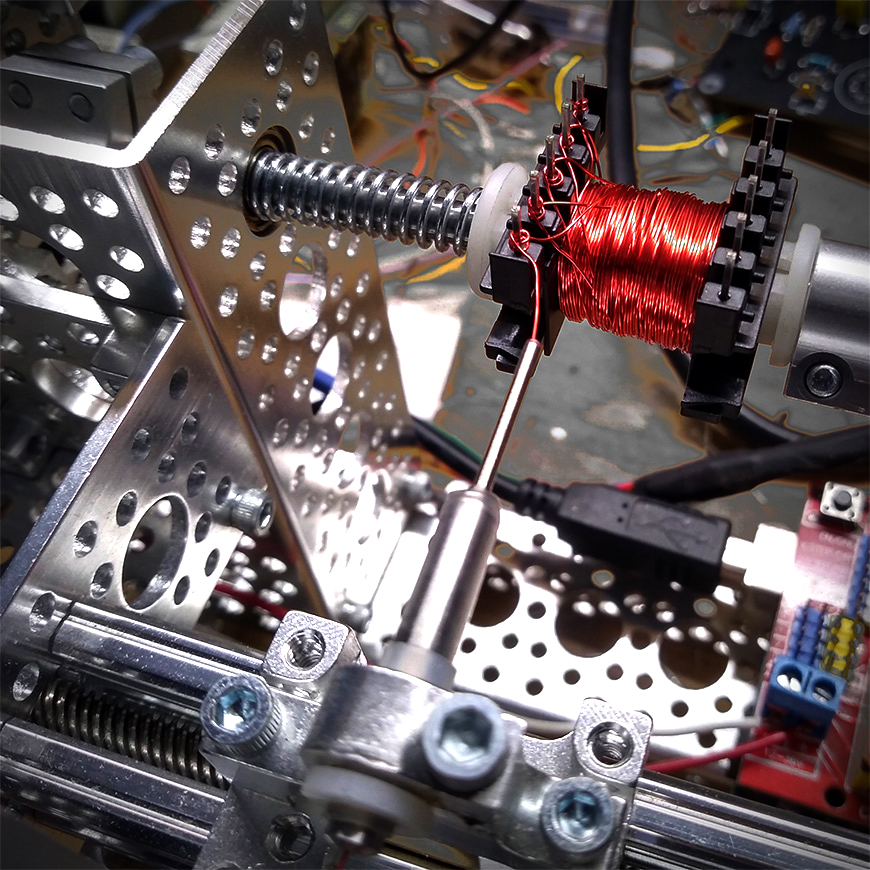

To build the inductor, we need to coil enameled wire (aka magnet wire) around a “bobbin”. It’s just a hollow spool, but will eventually have the core inserted.

Now for that machine code… we’ve also built our own machine to wind our inductors. It’s faster than manually doing it, and it isn’t prone to human error. Using precision motors, we can do everything like set the tension of the wire, and turn the wire around the bobbin to within 0.2 degrees of accuracy. If and when we need to make a “tap”, the machine pauses to allow us to make the tap out to a pin, then continues it’s journey where it left off. It’s not self-aware yet, but we’re working on that 😉

After the machine has completed its work, we insert the cores into the bobbin and perform an initial measurement of the different inductance taps.

After the machine has completed its work, we insert the cores into the bobbin and perform an initial measurement of the different inductance taps.

Once we’re satisfied, we permanently fuse the cores together so they are mated for life. Even the slightest movement of the cores can drastically impact the inductance values. Which will then impacts how well it can impede frequencies. So every core permanently belongs to that specific coil that was created for them. It’s a symbolic relationship that can be very prolific if you think about it. Each one is unique.

Every Elektrophonik inductor is specifically created for their set of chosen cores, and as such need to be made from scratch. After which they are tested to ensure less than a 0.1% error margin, kissed by angels, and put into service.